Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

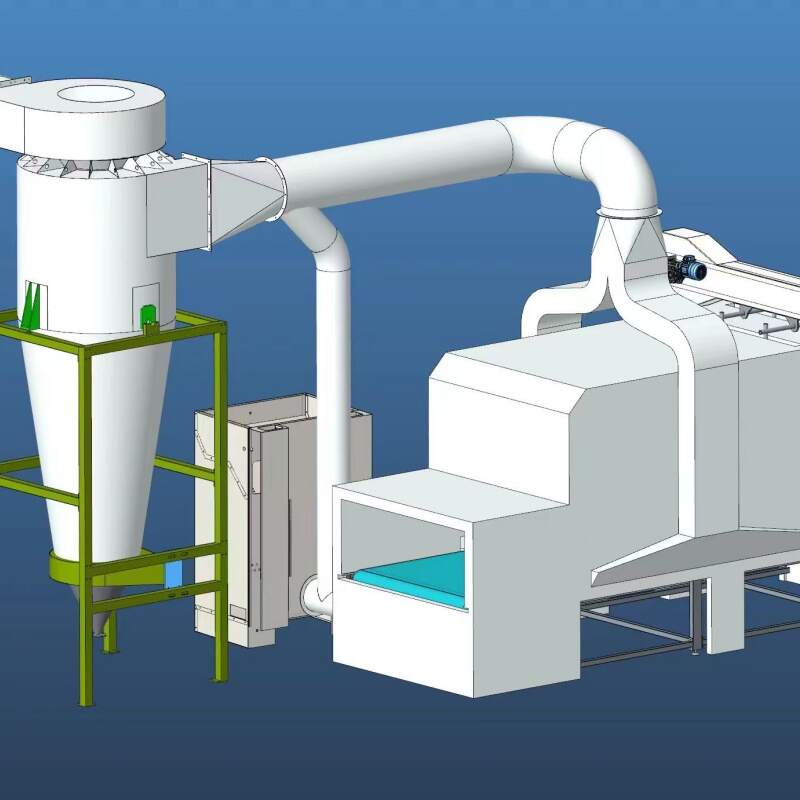

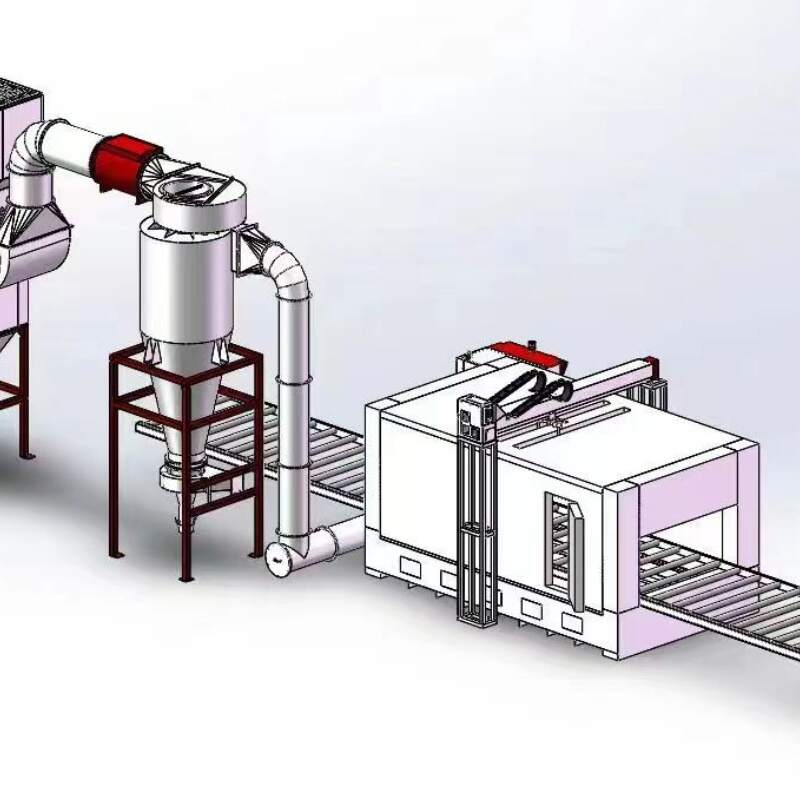

Auto Flat Spray Coating Line

The Automatic Flat Spray Coating Line is specially engineered for high-efficiency powder coating of flat workpieces such as steel plates, cabinet doors, panels, and sheet metal components. With fully automated spray guns, intelligent motion control, and seamless integration with conveyor systems, this line delivers consistent finishes, reduced labor input, and fast turnaround times.

Whether used in furniture, electrical, construction, or metal fabrication industries, this system guarantees a smooth, durable, and uniform surface finish — maximizing both product quality and production throughput.

Key Features & Advantages

Optimized for Flat Surfaces

Designed to handle flat and moderately contoured components with excellent edge coverage and no powder pooling.

Fully Automatic Coating System

Reciprocating automatic spray guns are synchronized with line speed for precise powder application and reduced overspray.

Dual-Side Spraying (Optional)

Configurable with top-only or top-and-bottom spray booths, enabling complete coverage in one pass.

High Production Efficiency

Ideal for batch or continuous production of panels with rapid color change options and short cycle times.

Eco-Friendly Design

Includes a powder recycling system with cyclone + filter modules to minimize powder loss and environmental impact.

Smart Control Interface

PLC + touchscreen system with recipe memory for quick production setup and fault diagnosis.

Application Scenarios

- Electrical cabinet doors and panels

- Steel, aluminum, or galvanized sheet products

- Elevator door panels

- Furniture backboards and tabletops

- HVAC panels and ventilation covers

- Industrial control box exteriors

Perfect for manufacturers looking to upgrade their flat product finishing to a more automated, clean, and consistent process.

Optional Configurations

- Quick color-change powder booth

- Automatic loading/unloading system

- Dual-lane conveyor for higher throughput

- Infrared + hot air hybrid oven for energy savings

- MES/SCADA integration for intelligent factory upgrades

Frequently Asked Questions

Q: How thick can the coating layer be?

A: Typically between 60–120μm depending on application needs; thickness can be adjusted via spray gun settings.

Q: What materials can be coated?

A: Steel, aluminum, galvanized steel, and other conductive flat sheet metals are supported.

Q: Is this line suitable for small batch production?

A: Absolutely. It supports both continuous and batch production modes, and quick setup allows frequent product changes.